|

Eager Space | Videos by Alpha | Videos by Date | All Video Text | Support | Community | About |

|---|

I got a subscriber question about how rocket designs are optimized, and when I went to write a short answer, I realized I couldn't. I needed to do a long answer.

This video explores some of the tradeoffs when optimizing a rocket design.

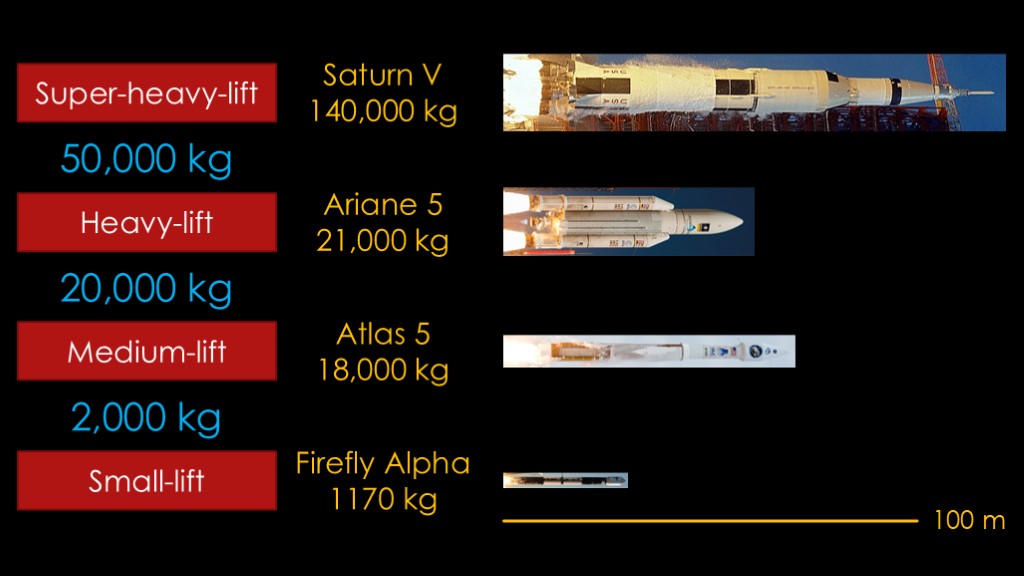

First, we need to decide what size of rocket to build.

There are small lift rockets that can lift up to 2000 kilograms into low earth orbit. An example is the Firefly Alpha, which can lift 1170 kilograms.

Next up is medium lift, with payloads up to 20,000 kilograms. Atlas V can lift 18,000 kilograms.

Heavy lift is up to 50,000 kilograms, and Ariane 5 just makes it with a payload of 21,000 kilograms.

And finally, anything above 50,000 kilograms is super-heavy-lift. The Saturn V with a payload of 140,000 kilograms is in this class, and it completes our list of rockets with 5 in their names.

I regret I could not find a well-known small lift rocket with "5" in its name.

Rocket design always starts with the engine, because without an engine you aren't going anywhere.

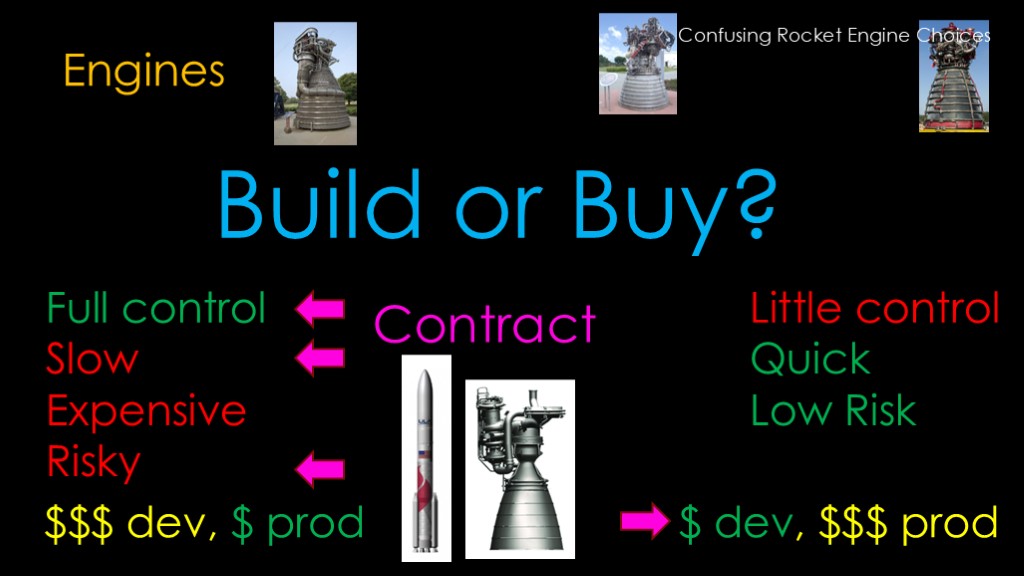

Your first decision to make is an important one - are you going to build an engine or are you going to buy an engine?

If you build, you have full control over the project. You get to choose how big the engine is, what propellants it uses, the engine cycle, how stressed the engine will be - hundreds or thousands of little choices. That's the good part.

The downside is that engine development is slow, and it's also expensive. You will need to build a lot of hardware and break a lot of hardware to get your engine to work, and you'll need expertise that is a little hard to find.

This plan is therefore risky; your rocket might be sitting around waiting for the engines to work.

Overall, you put a lot of dollars into development, but when you start making engines, they should be relatively cheap.

If you are buying off-the-shelf, you are limited to what is available from engine manufacturers, and there are few choices. But what they have is already available, so you can get engines quickly and they will work.

You spend very little money on development, but those engine companies want to sell you engines that cost as much as possible, generally in the "tens of millions of $$" range. And you are dependent on them; without their engines, you do not fly.

If you want to know more about this approach, see my video "confusing rocket engine choices" where I talk about the engine selections for the Atlas V and Delta IV rockets.

There is a hybrid approach, where you contract with another company to make an engine for you. This gets you full control, but it's going to be slow and risky, and in the end you are going to end up with high production costs. ULA chose this option for their upcoming Vulcan rocket, with the BE-4 engine from Blue Origin. Delays in engine development have delayed the first flight of Vulcan from 2019 to 2022, perhaps later.

Navigating this choice is very complicated.

The engine choice dictates what fuel the rocket will use and how big the rocket will be.

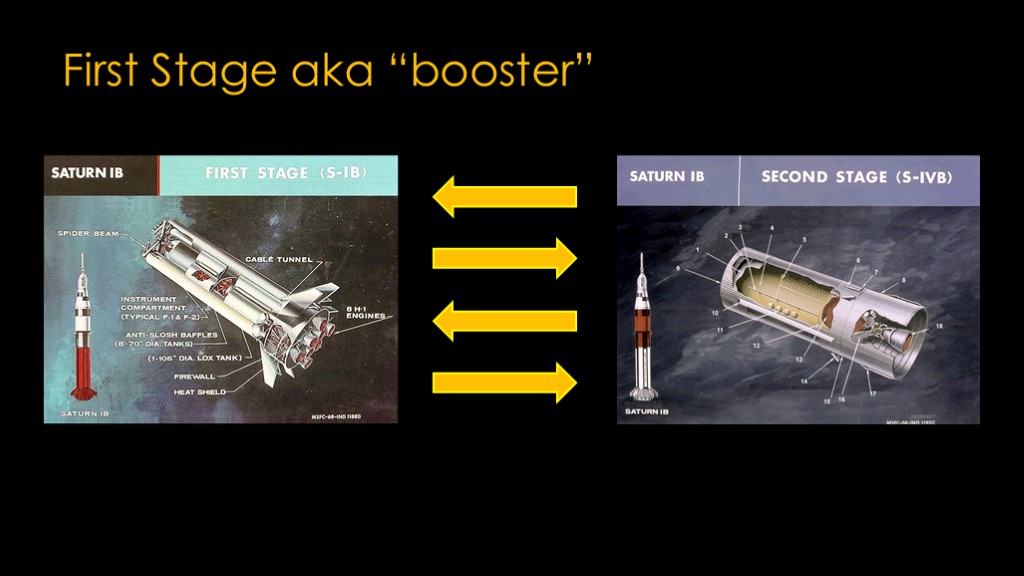

Now that we've decided on which engine to use, we can start designing our first stage.

In reality, the design process is an iterative one where decisions made about the second stage impact the first stage and decisions made about the first stage impact the second stage.

I'm starting with the first stage because it's a little bit simpler.

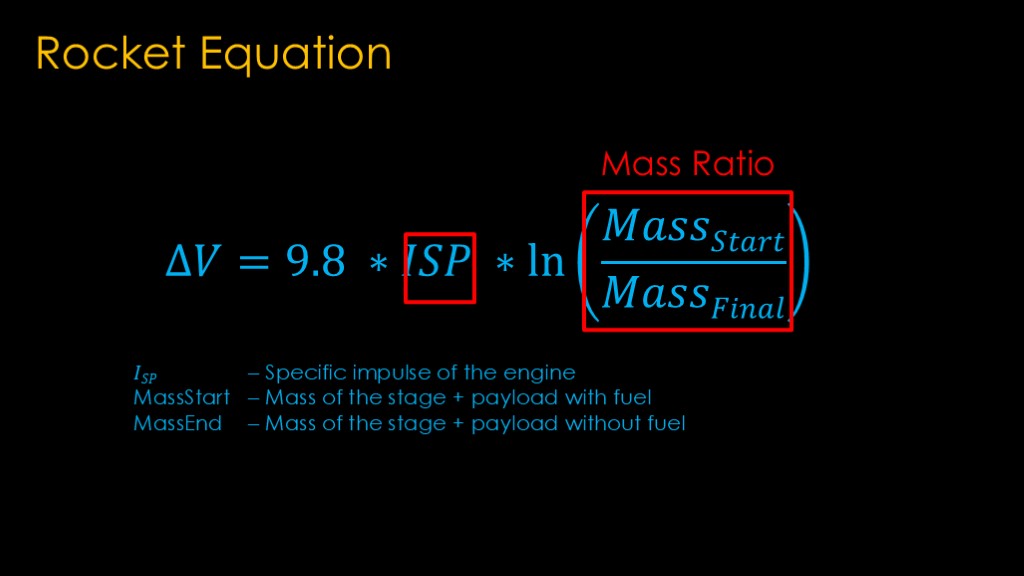

We'll start with the rocket equation, to figure out how much delta v - how much useful work - our rocket stage can do.

The delta v is 9.8 times the specific impulse times the natural log of the starting mass divided by the final mass.

The specific impulse is determined by the engine and propellants that we've chosen, so what we care about is the term with the masses in it. This is known as the mass ratio, and our goal is to maximize it.

To do this, we want the minimum rocket and the maximum propellant

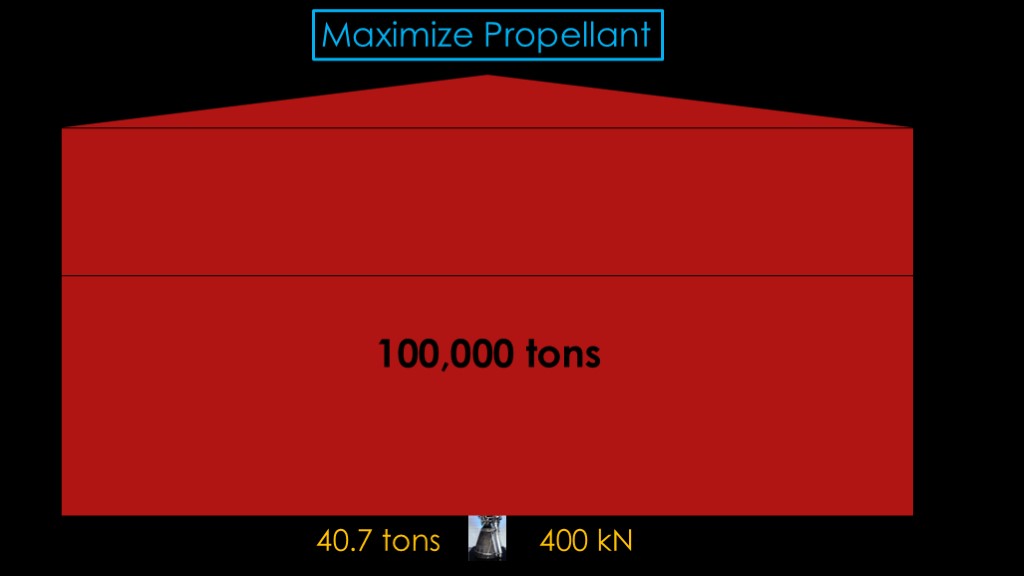

We'll therefore build a massive rocket, put one engine on it, fill it with propellant, and the rocket equation says it will have a massive delta v.

The obvious problem is that our little engine puts out 400 kN of thrust, or about 40.7 tons, while our rocket masses something like 100,000 tons.

That gives a thrust/weight ratio of 0.000407, and it's very clear that it cannot get off the pad.

So it can't just be about maximizing propellant - thrust/weight also matters.

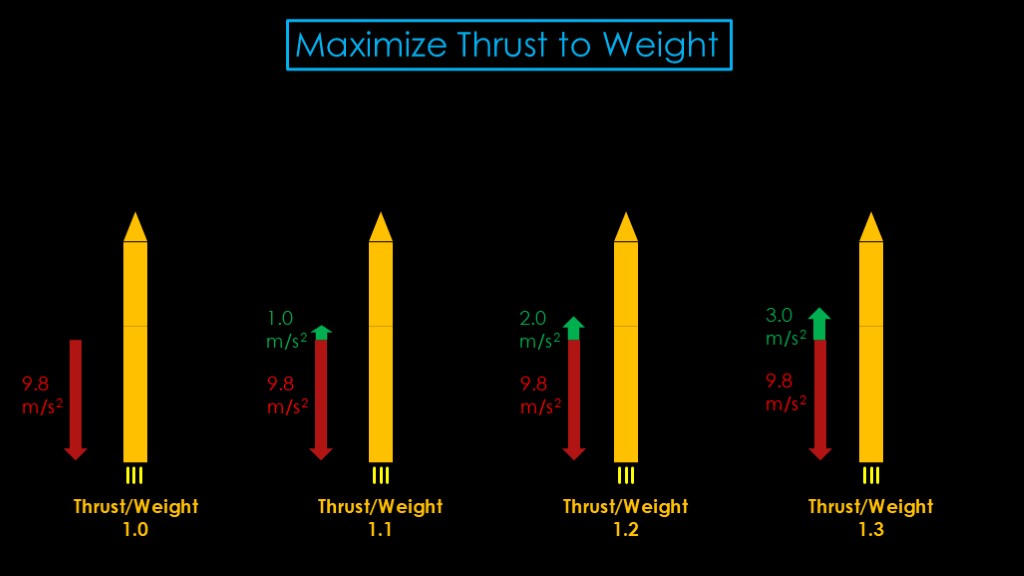

Here are four rockets with different thrust to weight ratios. They are all burning the same amount of fuel per second and producing the same thrust.

The first rocket has a thrust to weight ratio of 1.0. Gravity is pulling down at 9.8 meters per second squared, and the engines can produce exactly that amount of acceleration.

The second rocket is a little lighter and has a thrust to weight ratio of 1.1. Gravity is pulling down at 9.8 meters per second squared, and the engine is producing a little more than that, so there is enough extra to accelerate the rocket upwards at about 1 meter per second squared.

The third and fourth rockets have thrust ratios of 1.2 and 1.3, and achieve accelerations of about 2 and 3 meters per second squared.

The amount of energy spent just fighting against gravity are known as gravity losses.

If we launch these rockets, all of them burn the same amount of propellant, but the higher thrust/weight ratio gets more useful work done, so it is more efficient. If we continued the animation, the higher thrust/weight rocket gets to its desired altitude and velocity faster, and therefore wastes less energy on gravity losses.

Which means that we should maximize thrust to weight to minimize gravity losses.

What happens in the first 5 seconds?

At thrust/weight of 1, the rocket just hovers. While at thrust/weight of 1.3, it moves reasonably quickly.

As soon as the rocket is off the pad, it spends some of its thrust fighting against gravity, and the fuel to generate that thrust is fuel that is not used to do useful work.

Those losses are known as gravity losses, and our goal is to minimize them.

Show hovering test flight?

Which presents a bit of problem.

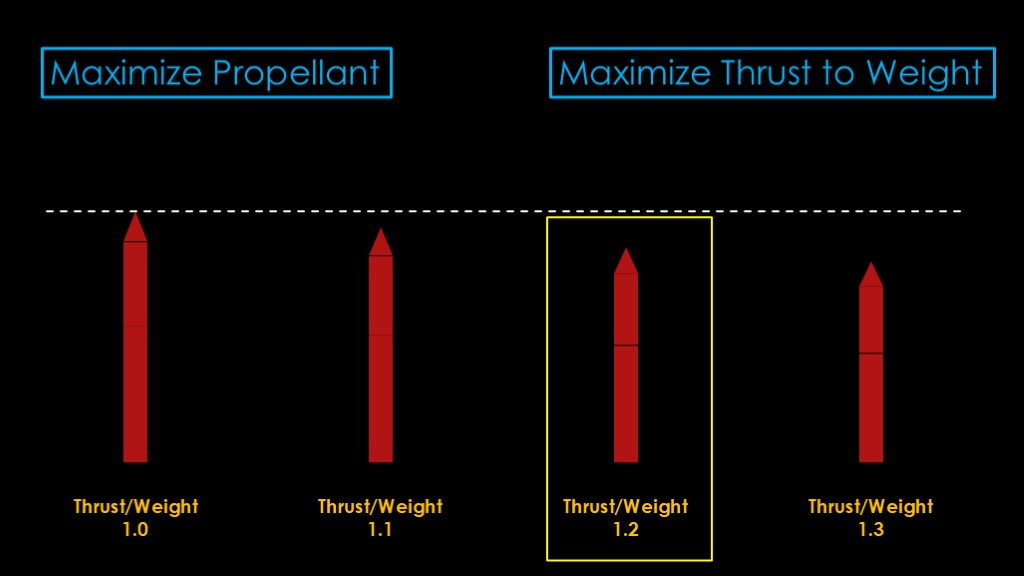

We want to maximize propellant to maximize the mass ratio, but we want to maximize the thrust to weight ratio to increase efficiency, and that requires reducing propellant.

There's one more factor to discuss; carrying more propellant requires a larger and heavier rocket, so the benefits of maximizing propellant are less than you would expect.

As a rule of thumb, most times the takeoff thrust/weight ratio is about 1.2 as that tends to give the best result.

Here's an interesting demonstration of low thrust/weight flight. On August 28, 2021, an Astra rocket suffered an engine failure right at launch.

That took their thrust/weight ratio from a healthy 1.25 down to 1.0, and had the following result.

Let's look at a real-world design example

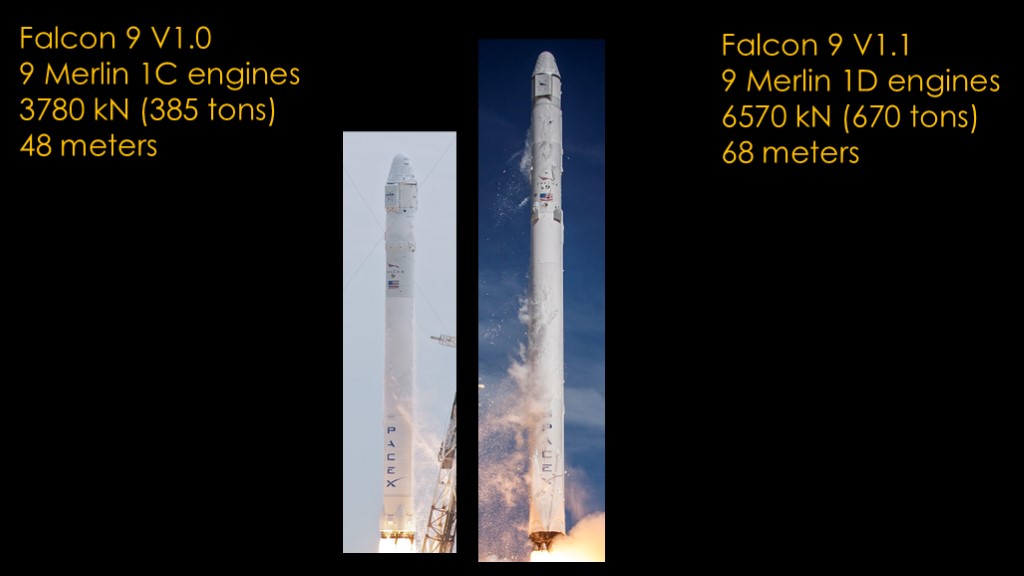

The initial Falcon 9 had 9 Merlin 1C engines that put out a total of 3780 kN, or 385 tons of thrust. It was 48 meters tall.

The replacement was the Falcon 9 V1.1, which used the uprated Merlin 1D engine that produced 73% more thrust. That would have pushed a thrust/weight ratio of 1.2 all the way up to 2.0, which means we would be wasting delta v.

The rocket was therefore stretched to contain more propellant.

But the stretch wasn't a 73% stretch, due to a specific constraint that Falcon 9 has.

SpaceX chose to transport the falcon 9 by road from their California factory to Florida, and that limited its diameter to 3.7 meters.

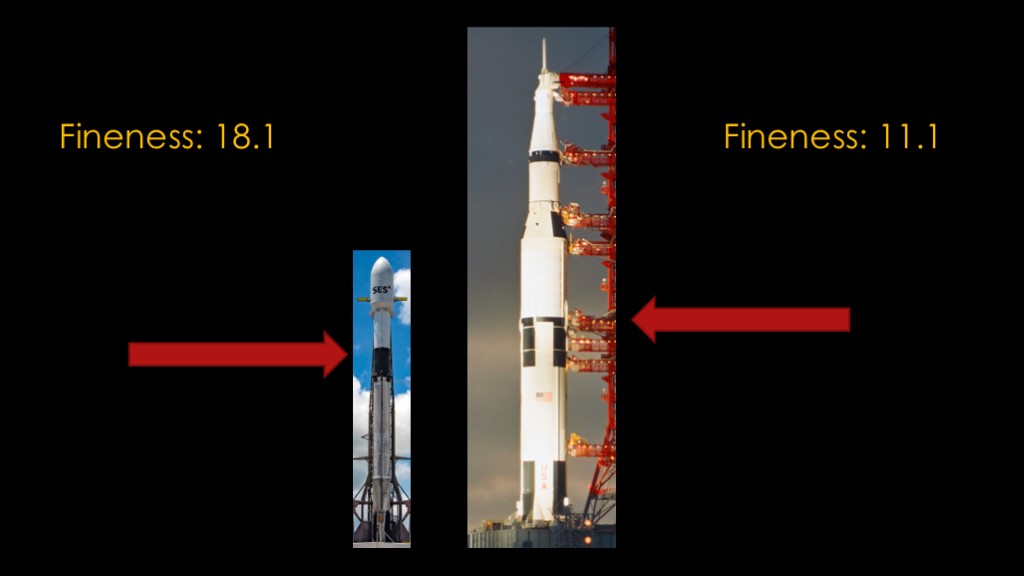

Here we show the falcon 9 next to the Saturn V. Very obviously, the Saturn V is much beefier.

Let's say that each of these rockets was hit with a big gust of wind during launch. Which one do you think would be better able to resist bending?

The answer is "the beefy one".

There is a technical measure known as "fineness", which is simply the height of the rocket divided by the diameter. The fineness of Falcon 9 is 18, and the fineness of Saturn V is 11.

Falcon 9 has the thrust to carry more propellant, but it can only get taller and that makes it too fine.

There's one more trick that SpaceX plays.

The Falcon 9 first stage has a large liquid oxygen tank on top and a smaller RP-1 fuel tank on the bottom. On most rockets, the liquid oxygen is at 90 kelvin, and the RP-1 is at around 283 kelvin.

If we take that liquid oxygen and chill it more - subchill it - down to 66 kelvin, it gets more dense and takes up less space. That allows them to store 10% more liquid oxygen in a given sized tank.

They do the same trick with the RP-1, but if you cool RP-1 too much it gets thick and that's bad for engines, so they only gain a little extra fuel - about 3%.

The idea of subchilling liquid oxygen is an old one; the Russians used in on their NK-33 engine back in the 1970s.

Our general design approach is to store enough propellant to hit a thrust to weight ratio of around 1.2

But what if the available engines are too weak for the amount we need to lift?

There are two solutions:

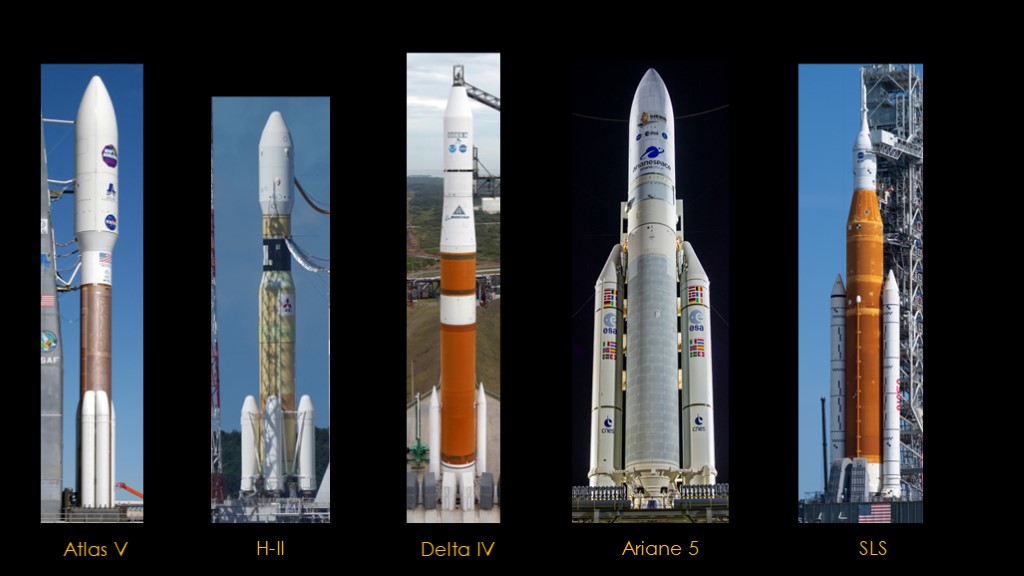

One classical approach is to add solid rocket boosters.

You can customize your thrust based on your payload by adding one or more small solid rocket boosters, as shown by the Atlas V, H-II, and Delta IV medium.

Or you can just go for high performance by using very big solids, as shown by the Ariane 5 or the SLS.

This is a good strategy if you buy your engines or if you don't have room under your vehicle for more engine nozzles.

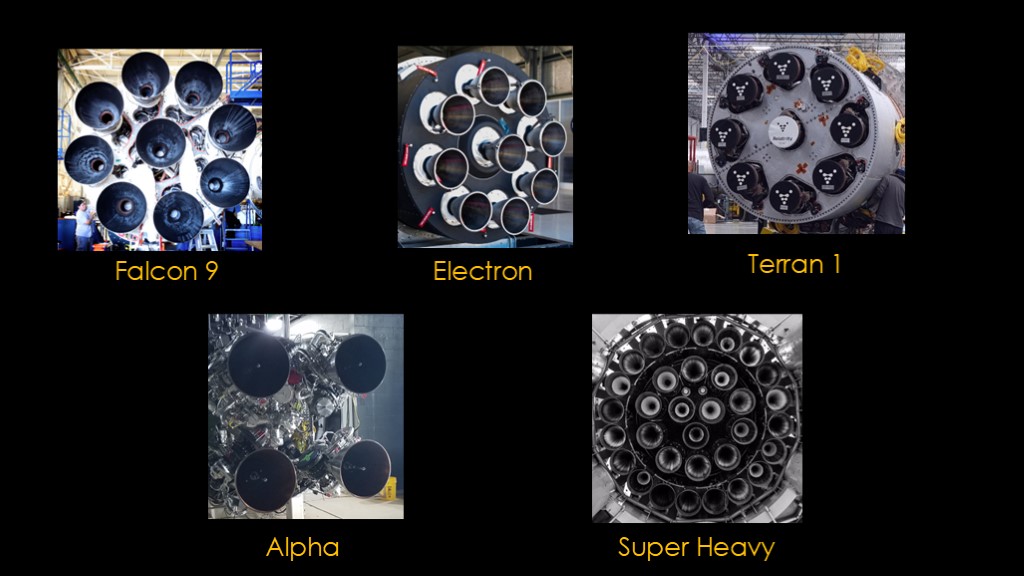

If you build your own engines, the answer is simple - you use a cluster of low-cost small engines rather than trying to build a big engine. Much easier to develop a smaller engine and build a lot of them, and that gives you the option to use the same engine on the upper stage.

What you're really looking for is to get as much thrust as possible inside the diameter of the rocket you are building, and multiple small engines are good at that.

Which ones of these can you name?

We'll start with the operational rockets: We have the Falcon 9 from SpaceX and the Electron from Rocket Lab, both using 9 engines, and the Alpha from Firefly using 4 engines.

The Super Heavy is next with 33 engines, followed by the Terran 1 from Relativity with 9 engines.

Looking at other planned rockets, I found lots of engines - 7, 4, 9, 9, 5, 7, and 7. The only one I found with one engine used a solid.

Larger clusters - roughly 7 engines or more - also give the opportunity to land the first stage for reuse.

Time to move to the second stage.

Earlier I said that first stage design affected second stage design and vice versa. This is best illustrated by looking at two launchers that take significantly different approaches.

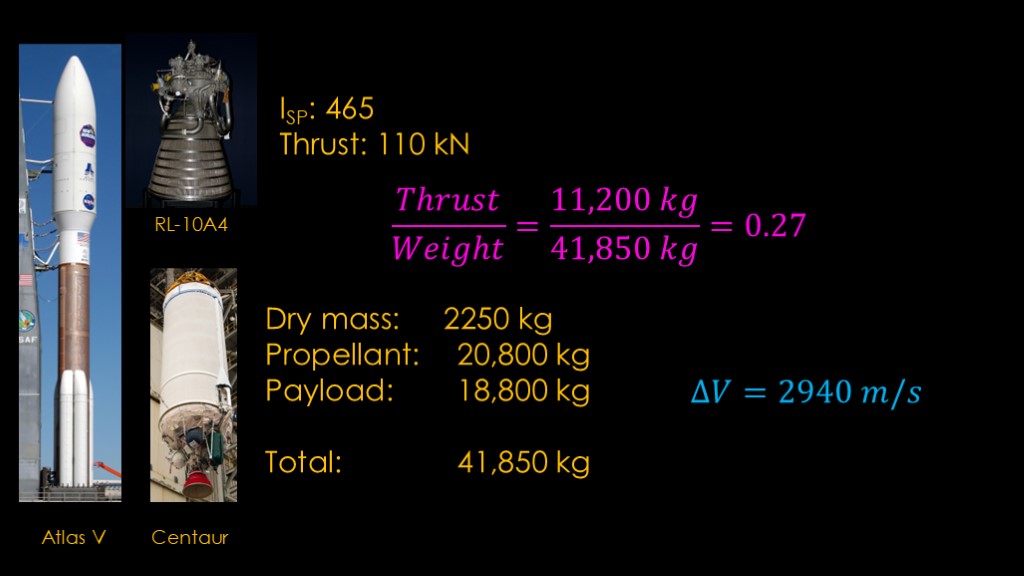

Our first example is the Atlas V. The centaur second stage is powered by one or two RL-10 engines, which have a long heritage - they were the first successfull US engine that used liquid hydrogen and liquid oxygen.

The centaur was first flown on the Atlas Centaur in the 1960s. And subsequently, on the atlas II, atlas III, Titan IIIE and Titan IV Centaur.

It has been a very successful second stage, and since the engine and stage were available, Lockheed Martin chose it for the upper stage of the Atlas V.

With a specific impulse of 465, the RL-10 is a very efficient engine. But with a thrust of only 110 kN, it's also a pretty wimpy engine. You could add another engine, but they are expensive; Aerojet Rocketdyne doesn't release prices but most reports put it in the $10-20 million range. It's expensive because they are expensive to make, the market is small, and they want to maximize their profits. A second engine adds a lot of cost to your rocket.

Let's look at some statistics for centaur. With a single engine, it masses 2250 kg and carries 20,800 kg of propellant. The maximum Atlas V payload to LEO is 18,800 kg, so the total mass is 41,850 kg.

With this information, we can now calculate the thrust to weight, and it turns out to be 0.27. Which is significantly less than 1.0. What is going on?

It turns out that the proper way to calculate thrust/weight for second stages is different and there is no firm requirement they reach a specific number.

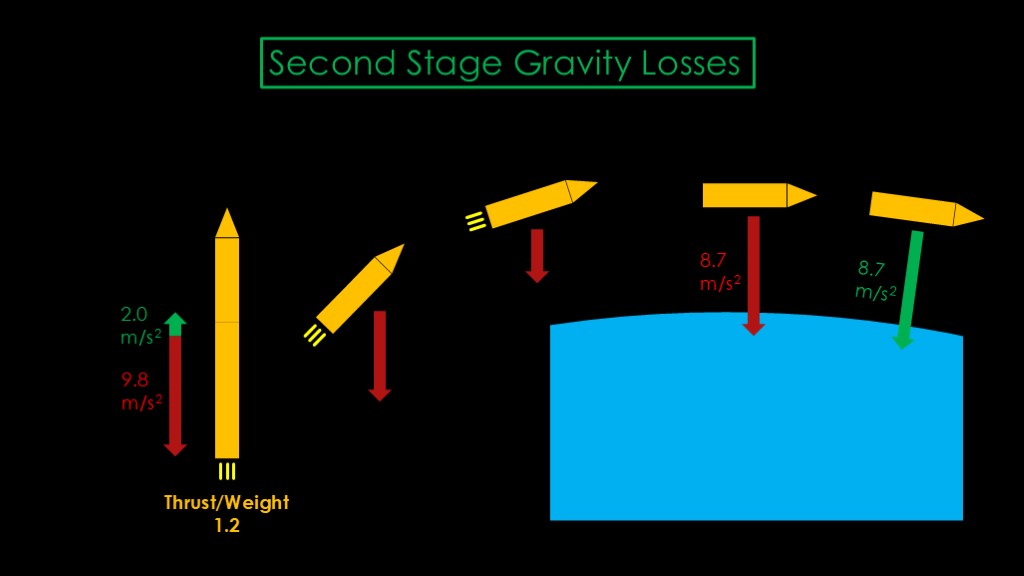

Gravity losses on second stages are a bit different than the first stage. At launch, our rocket was fighting against gravity, losing a full 9.8 meters per second squared of acceleration each second.

When we are in orbit, gravity is still pulling us down towards the earth, though the pull is smaller as we are farther away. Every second, that pull moves us closer to earth, but at the same time, the earth curves away from us the exact amount that gravity is pulling us towards the earth. That is in fact what it means to be in orbit. In orbit there are no gravity losses.

Which tells us that, as the velocity of the second stage increases during launch gravity losses will decrease until they are gone when we get to orbit. They therefore don't have as much impact on the second stage as they do on the first stage.

How can we utilize this for the Atlas V?

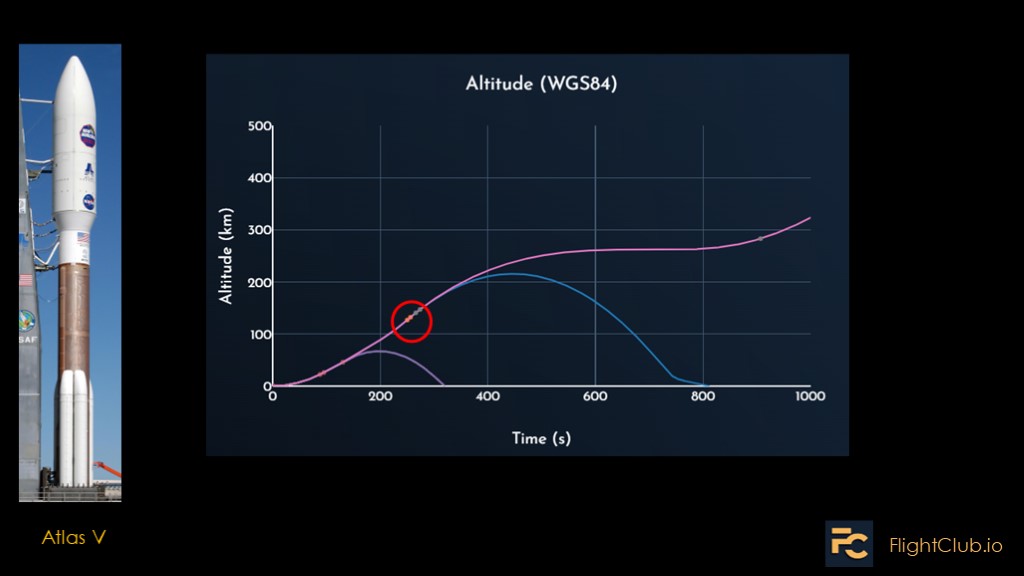

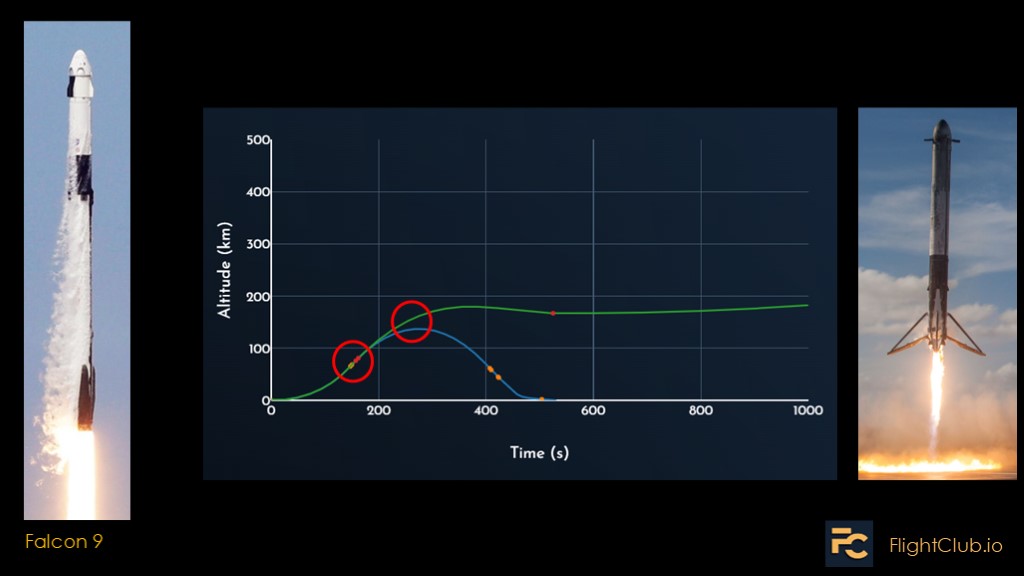

Here's an Atlas V launch graph from FlightClub.io. The first thing to notice is that the staging event occurs after about 250 seconds, or more than 4 minutes into flight. That's nearly halfway to orbit.

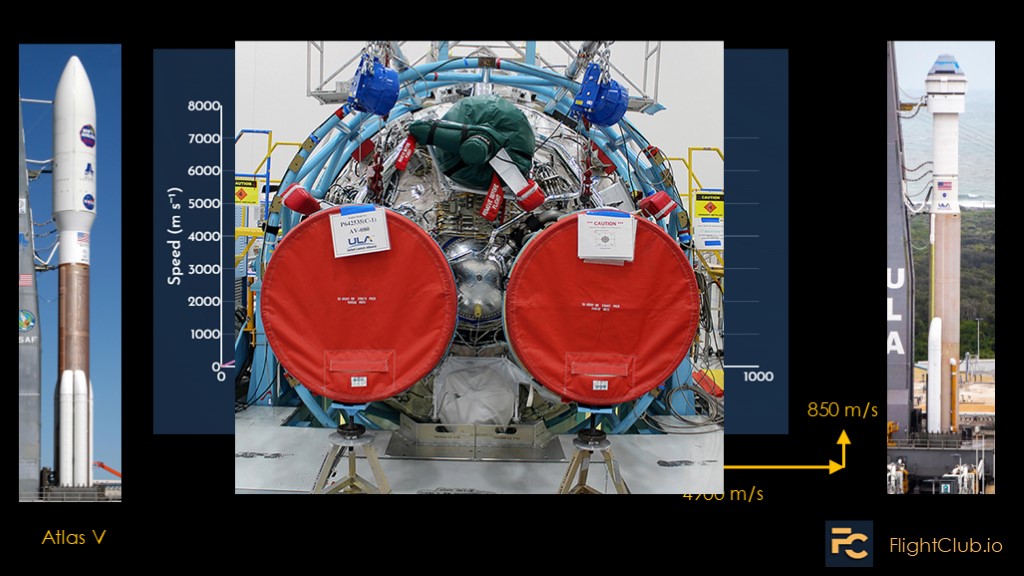

Let's look at a velocity graph.

Here we see that at the point of staging, the velocity of the vehicle is about 5000 meters per second. At this point, the velocity is 4900 meters per second horizontally and about 850 meters/second vertically. That vertical velocity comes in very handy; the second stage doesn't need to direct its thrust against gravity because the first stage has already done most of the work for it. The second stage can concentrate on horizontal velocity.

And it really needs the help; note how slowly the second stage gains velocity, because of the low thrust of the RL-10.

This is known as a "lofted trajectory"; the second stage is tossed up higher to make up for its weaker thrust.

This works just fine in most cases, but for crewed missions, the lofted trajectory would impose higher g loads during some abort scenarios.

The Atlas V used with the Boeing Starliner Capsule therefore uses a centaur with two RL-10 engines. That doubles the thrust and permits using a trajectory with much less loft.

Using this data we can calculate the delta v for the centaur stage with this payload, and it turns out to be 2940 meters per second.

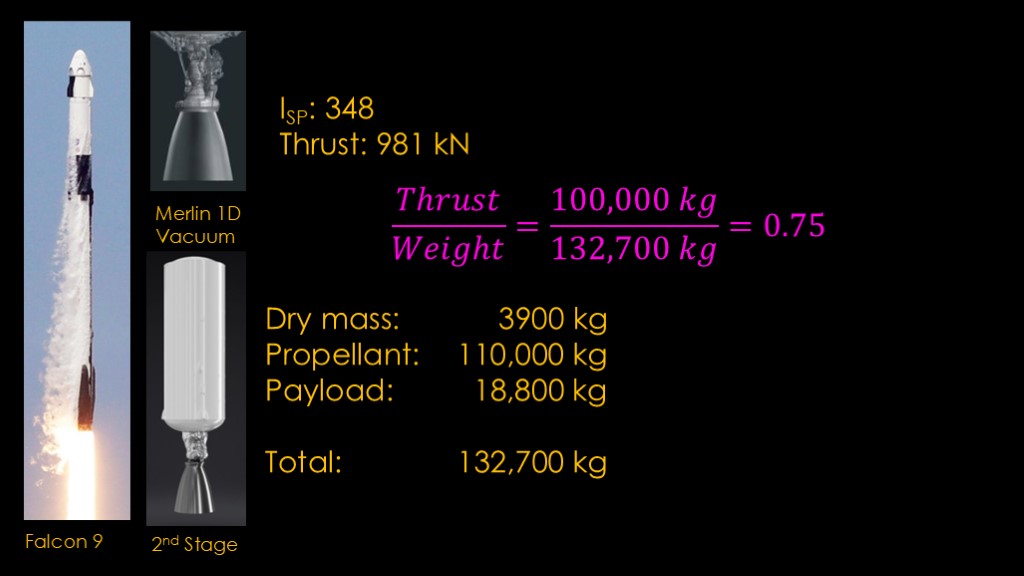

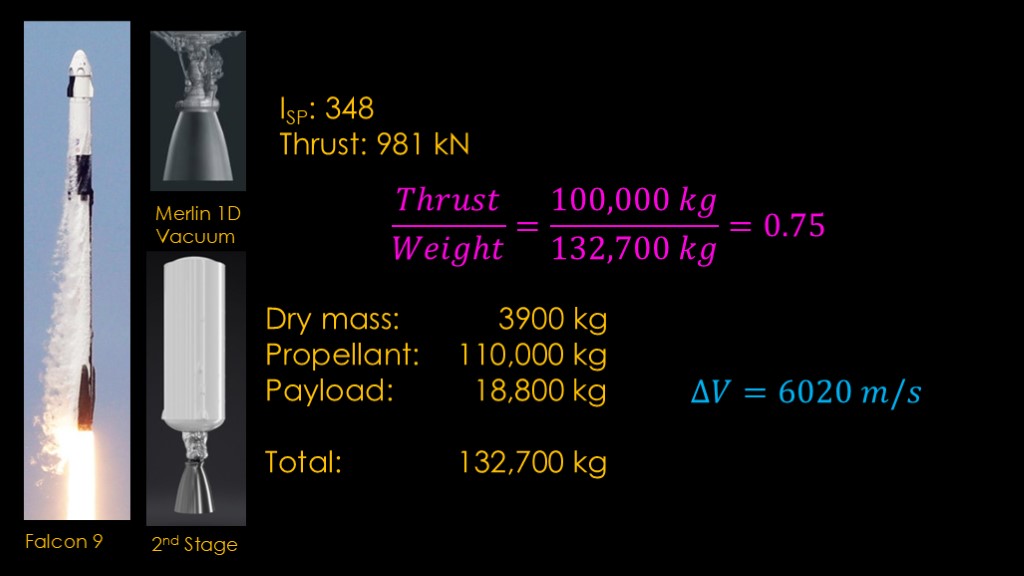

We will now look at the Falcon 9, which uses a very different approach. The second stage is powered by a merlin 1D Vacuum engine.

As a kerolox engine, it has an ISP of 348, quite a bit less than the RL-10's 465. But it has a thrust of 981 kN, roughly 9 times the thrust of the RL-10.

The stage is more massive than centaur, with a dry mass of 3900 kg and a huge propellant load of 110,000 kilograms. I arbitrarily set the payload to the same 18,800 kilograms as Atlas V, though it can theoretically do 26,000 kg to low earth orbit.

The thrust to weight ratio is 0.75, which makes this stage better equipped to fight against gravity.

Here's the time to altitude graph for the Falcon 9. Let's highlight where the Atlas V staged, at about 250 seconds.

The Falcon 9 stages much earlier in the flight, at about 150 seconds, and a speed of 2200 meters/second. The earlier staging and the beefier second stage means that the trajectory is less lofted.

The choice to use a beefier second stage that stages much earlier means that staging happens lower and slower, and that enables first stage landing and reuse.

The falcon 9 packs a lot of propellant into the second stage, giving it a great mass ratio, and a total delta V of 6020 m/s, a little more than double the centaur even though the centaur has a much higher specific impulse.

Which is not surprising; falcon 9 stages much earlier than Atlas V and therefore the second stage needs to do much more of the work to get into orbit, and that requires a higher delta v.

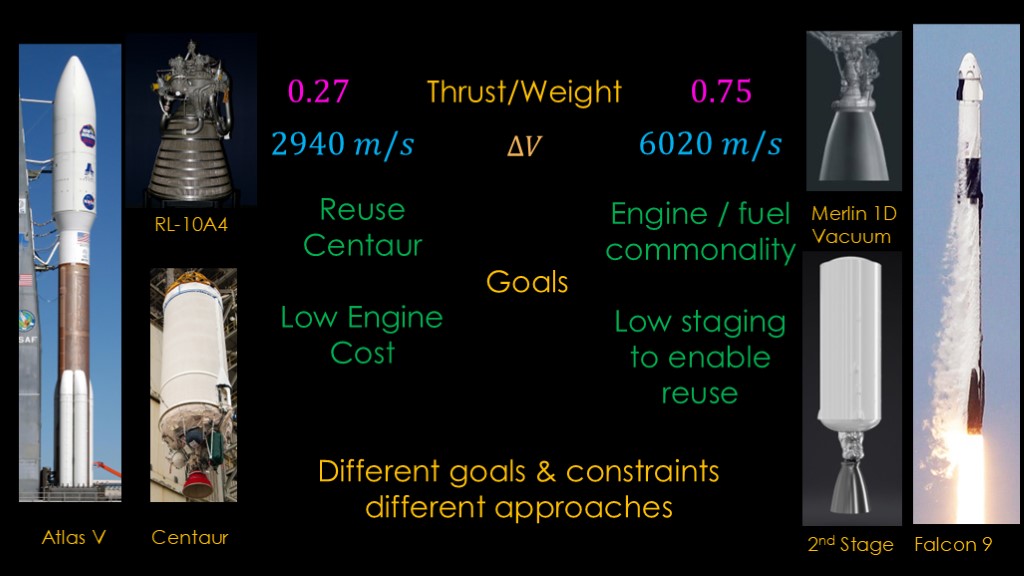

Let's compare the two approaches.

The thrust to weight of centaur is only 0.27, while the thrust to weight of the falcon 9 second stage is 0.75.

The centaur has about 2940 meters/second of delta v, while Falcon 9 gets 6020. The two stages are roughly the same size with centaur having a bit more volume, but it simply cannot pack much propellant into its tanks because liquid hydrogen takes up so much space, so it ends up with much less delta v. Atlas V deals with this limitation by staging later and using a beefier first stage that can do most of the work of getting the payload to orbit.

If we consider goals, the goal of the Atlas v was to reuse centaur and have low engine cost, and it achieved that. Falcon 9 wanted engine and fuel commonality across both stages, and it wanted low staging to enable landing of the first stage for reuse.

Different goals and constraints lead to different approaches.

Different missions will of course produce different optimization results, based on payload mass, destination orbit, trajectory constraints, and a number of other factors.

Thank you for your attention

If you enjoyed this video, please draw a picture of a centaur holding a falcon for me.